Bradford, West Yorkshire, United Kingdom – 29 July 2021 – UK 3D printing filament brand, Filamentive, has today announced the launch of Filamentive PRO – a specialised portfolio of high performance 3D printing polymers for engineering applications.

With hardware innovation enabling desktop FFF / FDM 3D printers to be capable of printing high temperature materials, high-performance polymers such as PEEK, PEKK, PPSU and ULTEM can now be utilised by engineers to create custom, high-value parts for critical applications.

Offering strength-to-weight ratios that surpass most metals, this next generation of high performance polymers have the capability to disrupt the automotive, aerospace, manufacturing and medical industries – so much so that the polyaryletherketone (PAEK) family, including PEEK and PEKK – are expected to account for nearly 19 percent of total polymer 3D print material revenues by 2026.

As per the 2021 Sculpteo State of 3D Printing Report, 49% of Power Users (3D printing in a work context with significant experience using the technology) say they use it for production. Furthermore, the industry has to meet the needs of end-use applications with new materials with 72% of users naming strength as the most important material property.

“With 3D printing increasingly utilised as a real production tool, Filamentive PRO seeks to meet the growing demand for high performance polymers used in industrial applications, whilst still upholding our central sustainability agenda.”

Ravi Toor – Founder & Managing Director, Filamentive

Filamentive PRO is made possible due to collaborative partnerships with Mitsubishi Chemical and LEHVOSS; the initial material portfolio will consist of:

- PEI ULTEM 9085

- PEI ULTEM 1010

- PPSU

- 3F PEEK CF 9676

- 3F PEEK 9581

- 3F PEKK 50082

- 3F PAHT 9825

- 3F PAHT 9936

- 3F PAHT CF 9891

- 3F PP CF 9928

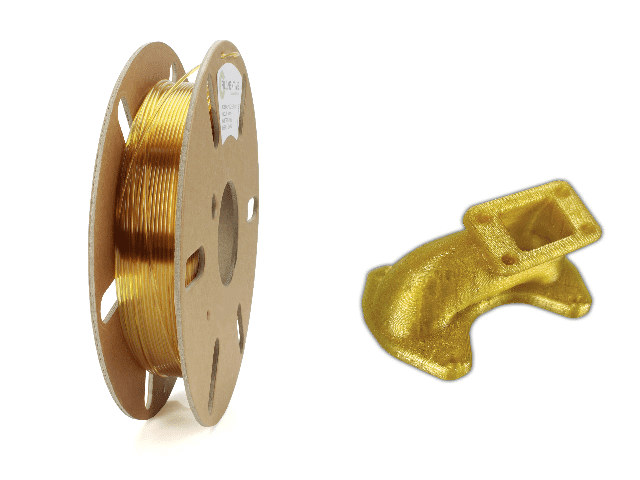

Sustainability remains a strong focus of Filamentive PRO. To reduce environmental impact, all materials sold will be spooled onto 100% recyclable cardboard reels, reducing waste and eliminating hard-to-recycling plastic reels. Furthermore, said polymers are inherently more hard-wearing and resistant than conventional 3D printing filaments such as PLA, enabling long-term, end-use applications – extending product life cycles and thus reducing the associated material input, energy use and wastage. Carbon offset is another sustainability initiative – Filamentive’s partnership with Ecologi ensures carbon emissions arising from production, transport and employee activity are now offset.

Mitsubishi implements KAITEKI – an original concept of the Mitsubishi Chemical Holdings Corporation Group that proposes a way forward in the sustainable development of society and the planet, in addition to serving as a guide for solving environmental and social issues. LEHVOSS have a proactive sustainability agenda and are signatories of the UN Global Compact – a commitment to supporting the Ten Principles of the United Nations Global Compact on human rights, labour, environment and anti-corruption.

High temperature filaments are used in applications that require high heat resistance, high strength and broad chemical resistance. All of which are UL 94-V0 rated. This includes:

- PEI ULTEM™ 1010 – an ultra-performance material with a glass transition temperature (Tg) of 217°C

- PEI ULTEM™ 9085 – a high-performance polymer with excellent mechanical performance

- PPSU – exhibits impact resistance and chemical resistance superior to ULTEM

- 3F PEKK 50082 NT – exhibits outstanding mechanical properties combined with excellent thermal, wear, and chemical resistance

- 3F PEEK CF 9676 – a polyetheretherketone reinforced with carbon fibre for improved stiffness and compressive strength

- 3F PEEK 9581 – unreinforced PEEK grade with metal-replacing capabilities

LUVOCOM® 3F Filaments are specially designed to provide an easy-to-print experience and to achieve another level of properties and quality. With LUVOCOM® 3F compounds, the LEHVOSS Group is offering materials specially optimised for 3D printing – enabling high-performance parts for industrial applications:

- 3F PAHT 9825 – a high temperature resistant polyamide (PA)

- 3F PAHT 9936 – excellent tensile and impact strength and allows continued operation up to 100°C – 120°C

- 3F PAHT CF 9891 – a 15% carbon fibre reinforced polyamide (PA6) with impressive material stiffness.

- 3F PP CF 9928 – a polypropylene (PP) copolymer reinforced with carbon fibres – suitable for continuous discharging of statically-generated electricity (ESD safe)

The full Filamentive PRO product range can be viewed at this link

A FREE Guide with technical data and print settings / requirements can be found here

Filamentive (https://filamentive.com – info@filamentive.com) is the market leader in sustainable materials for FFF 3D Printing. The company was founded to address the environmental need to use more recycled plastics in 3D printing, and also alleviate market concerns over quality and long-term sustainability. Filamentive has experienced rapid growth and continues to address the questions surrounding 3D printing recycled materials. Headquartered in Bradford, United Kingdom, its customers include a global network of makers, industry and education clients.

Trackbacks/Pingbacks